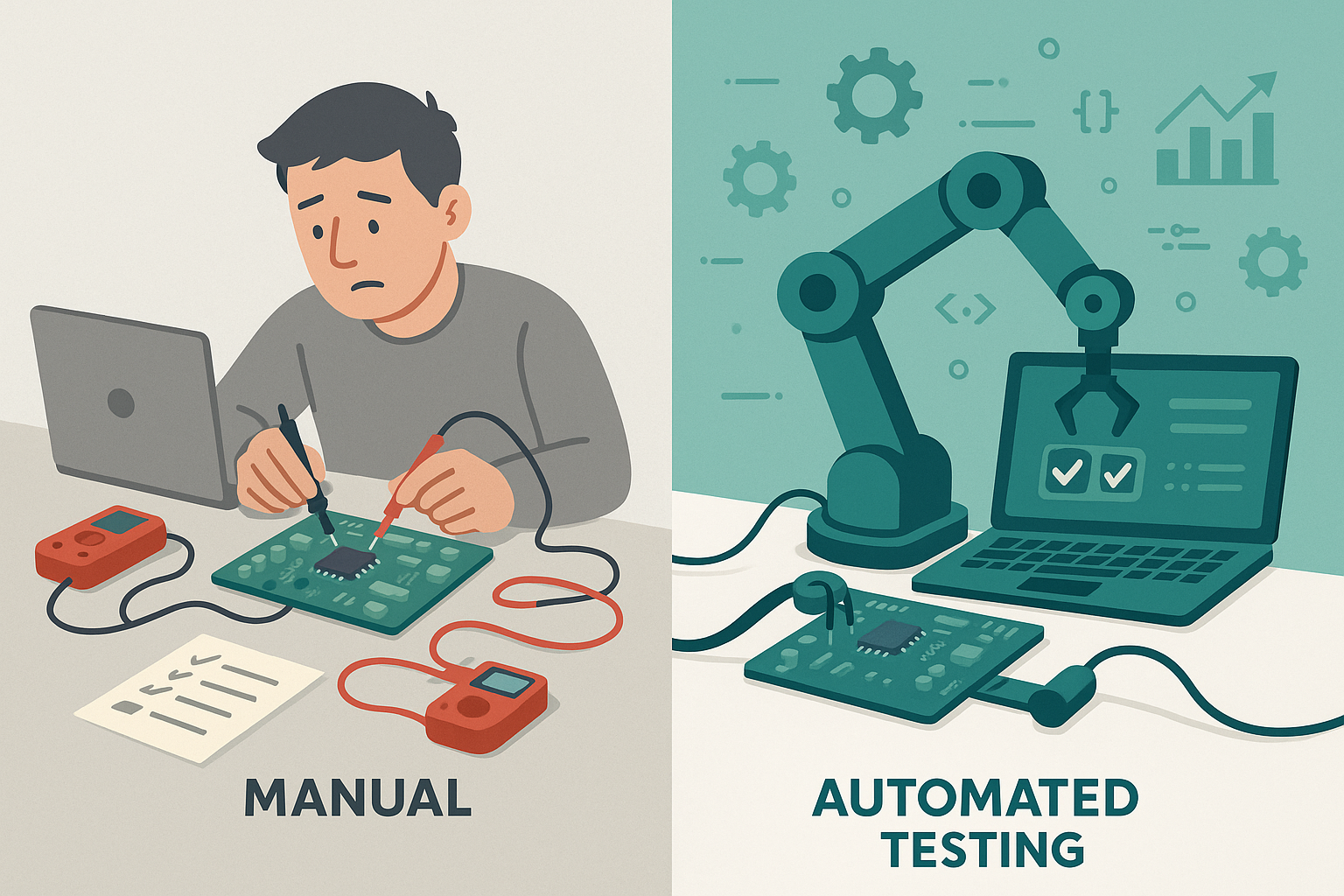

Manual testing vs. automated testing for Embedded Systems

Design Engineer.

21 July 2025

In the ever-evolving world of embedded systems, product complexity continues to rise. Devices today must deliver higher performance, support multiple connectivity standards, meet stringent safety regulations, and provide seamless user experiences. In such a demanding landscape, testing becomes a critical phase of the development lifecycle.

Yet, many companies still rely heavily on manual testing practices that, although seemingly cost-effective on the surface, often lead to major inefficiencies, missed bugs, inconsistent results, and ultimately, increased costs. In this article, we’ll explore the hidden costs of manual testing and show why modern embedded product teams must transition to automated testing frameworks like Embien’s TestBot.

The Pitfalls of Manual Testing in Embedded Systems

Manual testing is traditionally favoured for its simplicity and low upfront investment. It involves testers operating devices directly, validating firmware behaviour, checking interfaces, logging results, and repeating tests across builds. While this might be manageable in early development, it quickly becomes problematic as projects scale.

Scalability Bottlenecks

Manual testing simply doesn’t scale. As product variants increase, supporting each configuration manually becomes overwhelming. With embedded systems, small hardware or firmware changes often necessitate full regression cycles.

- Testing five variants? Multiply effort by five.

- Adding more sensors or protocols? Increase test cases exponentially.

Manual processes can't keep up. Automation, in contrast, lets you scale test cases across devices with minimal added effort.

Lack of Repeatability

In manual testing, outcomes often depend on the individual executing the test:

- Missed steps

- Inconsistent interpretation of pass/fail

- Human fatigue or distractions

This leads to variable results, making debugging harder and reducing confidence in quality gates.

High Labor Costs and Opportunity Loss

Time spent on repetitive tests is time not spent innovating. Skilled firmware developers or testers performing manual validation is both costly and inefficient.

- Manual testing is not free—it’s resource misallocation.

- Teams bogged down in testing struggle to meet deadlines or address product issues proactively.

Incomplete Test Coverage

Manual testing often focuses on functional paths. Rare edge cases, timing scenarios, and negative paths may get ignored due to time pressure. Without thorough testing:

- Bugs escape into production

- Product reliability suffers

Delayed Feedback Loops

Manual testing slows down the feedback cycle between development and QA. In fast-paced embedded projects, this delay hampers agility and increases the cost of defect fixes.

Manual Testing vs. Automated Testing: A Real ROI Perspective

Let’s break it down with a simple comparison:

| Feature | Manual Testing | Automated Testing (TestBot) |

|---|---|---|

| Test Speed | Slow, human-limited | Fast, parallel, 24/7 capable |

| Repeatability | Varies with tester | 100% consistent |

| Cost Over Time | High | Decreases with reuse |

| Test Coverage | Limited | High with broad scenarios |

| Integration with CI/CD | Difficult | Seamless with TestBot |

| Data Logging & Analytics | Manual, error-prone | Automated, structured |

| Resource Utilization | High human involvement | Minimal manual intervention |

Over time, the return on investment (ROI) of automated testing far exceeds that of manual testing, especially for companies developing multiple SKUs or targeting certifications like ISO 26262 or IEC 62304.

Introducing TestBot: Embien’s Automated Testing Framework

At Embien Technologies, we’ve built TestBot, a robust, flexible, and modular automated testing framework designed specifically for embedded system validation.

Key Features of TestBot:

Scalable Test Automation

- TestBot supports multiple hardware units simultaneously.

- Run thousands of test cases across firmware builds with ease.

Hardware-in-the-Loop (HIL) Integration

- Automate signal generation, sensor simulation, and peripheral monitoring.

- Suitable for ECUs, PLCs, HMIs, and IoT devices.

Support for Protocol Validation

- CAN, Modbus, I2C, UART, SPI, Ethernet, and more.

- Precise timing control and response monitoring.

CI/CD Friendly

- Integrates with Jenkins, GitLab CI, Azure DevOps for nightly/continuous validation.

Detailed Test Reports and Analytics

- Automatically logs results, graphs signal data, and highlights regressions.

- Supports traceability matrices for certification.

Reusable Test Scripts

- Write once, reuse across variants.

- Easy-to-update test logic as requirements evolve.

TestBot is not a generic tool—it is purpose-built for the challenges of embedded testing, and has been proven in domains like automotive, healthcare, industrial automation, and consumer electronics.

How TestBot Solves Manual Testing Challenges

Scalability

TestBot scales from single-board tests to full system validation, ensuring consistent execution across devices.

Repeatability

Removes human variability with deterministic test sequences and outcomes.

Speed

Accelerates test cycles from hours to minutes, facilitating faster iterations.

Coverage

Enables exhaustive condition testing including fault injection, edge case handling, and long-duration runs.

Traceability

Every test run is logged, timestamped, and reportable for internal QA or external audits.

Automotive Tier 1 Supplier

Needed nightly regression for ECU firmware with multiple CAN and LIN interfaces.

- TestBot ran 4,000 test cases per night across 10 hardware units.

- Reduced release cycle time by 35%.

Learn more about TestBot’s automotive solutions at TestBot Features.

Medical Device Manufacturer

IEC 62304 compliance demanded strict test traceability.

- TestBot enabled automated test reports mapped to software requirements.

- Enabled 100% test case coverage with zero manual logs.

Check out how TestBot supports compliance at TestBot’s Setup Guide.

Industrial Automation OEM

Product variants with different sensor configurations.

- TestBot scripts reused across all variants with parameterization.

- Reduced test engineering effort by 60%.

How to Transition from Manual to Automated Testing

- Start Small: Identify repetitive, high-value test cases for automation.

- Define Scope: Use TestBot’s modularity to focus on critical interfaces and expand gradually.

- Train Teams: Equip QA and developers to script and manage tests.

- Integrate: Embed TestBot into your CI/CD pipeline.

- Measure & Iterate: Use built-in metrics to identify gaps and improve test coverage.

Conclusion: Rethink Your Testing Strategy

Manual testing may seem easier, but it’s silently draining your resources and limiting your scalability. As embedded systems grow more complex and timelines shrink, your QA strategy must evolve.

Automated testing is not just a tool—it’s a competitive advantage.

With TestBot, Embien offers embedded product teams a battle-tested solution to eliminate bottlenecks, improve product quality, and shorten release cycles.

Stop relying on manual routines. Step beyond the workbench. Embrace the power of automated testing with TestBot and unlock the next level of embedded development.